Precision CNC Machining

FAST • RELIABLE • AMERICAN

We are certified to the ISO 9001:2015 standard. Every process is verified to meet your requirements.RAPID TURNAROUNDs

Big shop capacity, small shop agility. We move quickly and provide responsive service to our customers.

reliable results

ISO 9001:2015 certified quality management system ensuring high precision parts and on-time delivery.

American craftsmanship

Proudly manufacturing in Tulsa, Oklahoma since 2017. We are investing to strengthen the American supply chain.

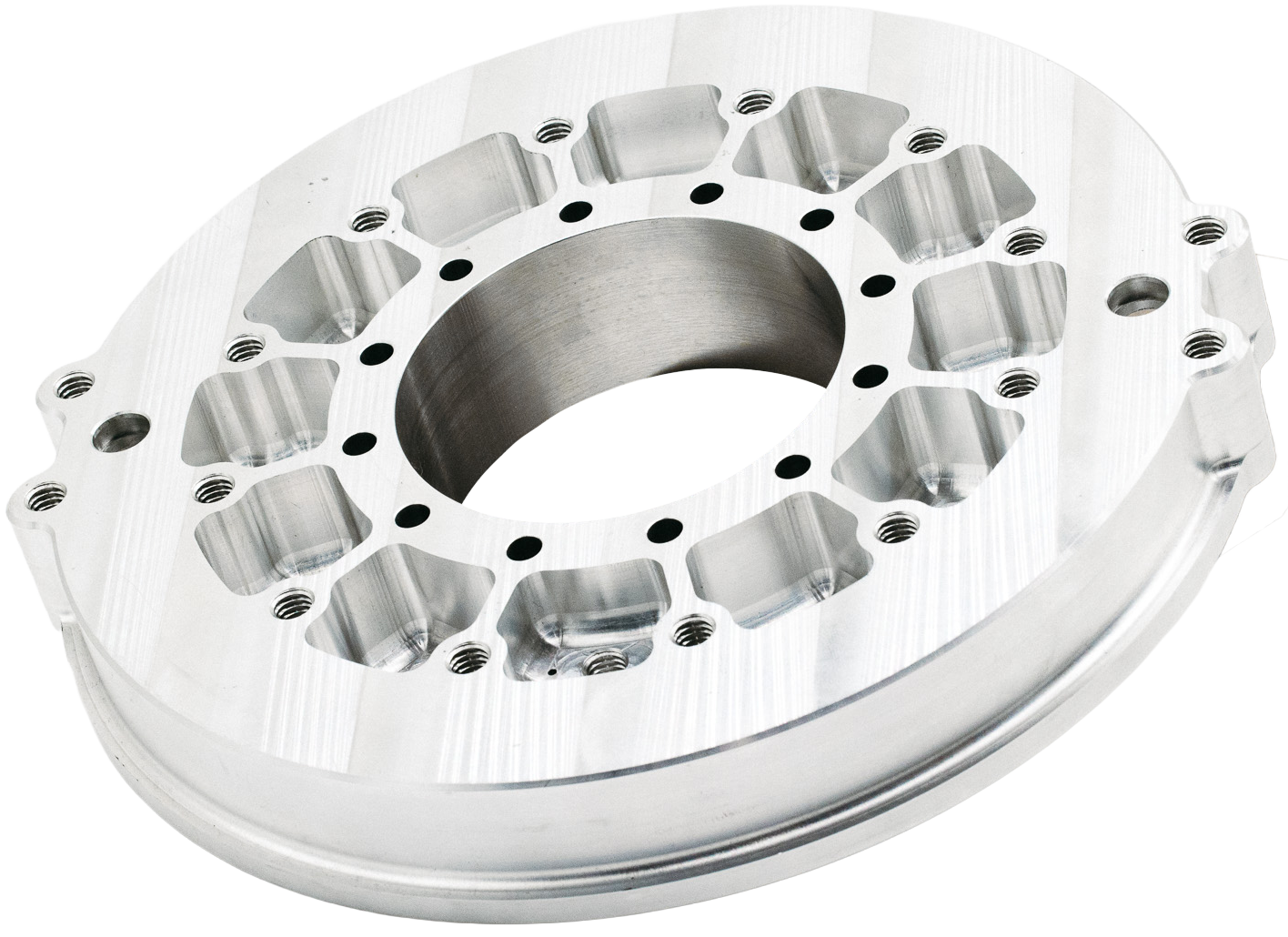

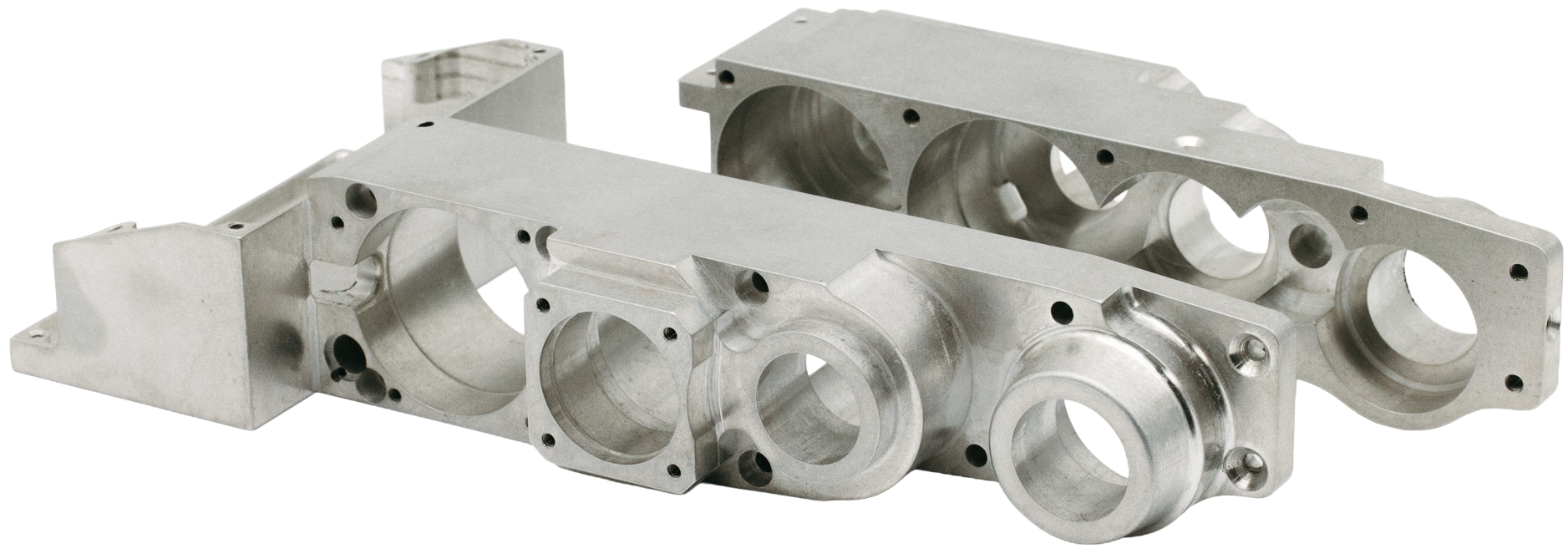

milling

Multi-Axis Milling: High Precision Parts Delivered Vast

Our vertical machining centers produce prototypes and runs with exceptional accuracy. We are introducing robotics into our machining processes to create additional efficiencies.

3 and 4-axis services; 0.0005” tolerances and a work envelope of 50”x23”x25”. We have you covered.

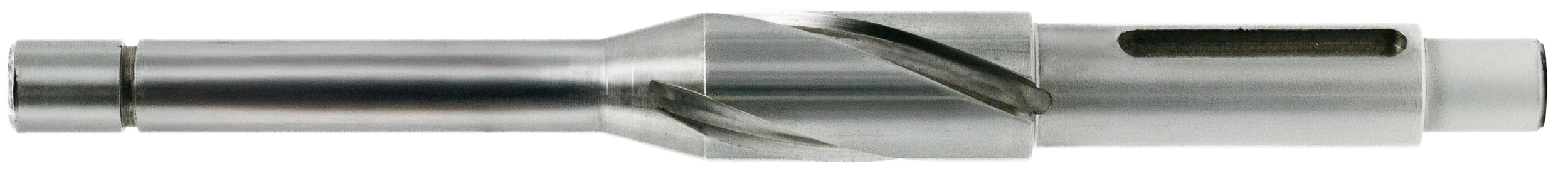

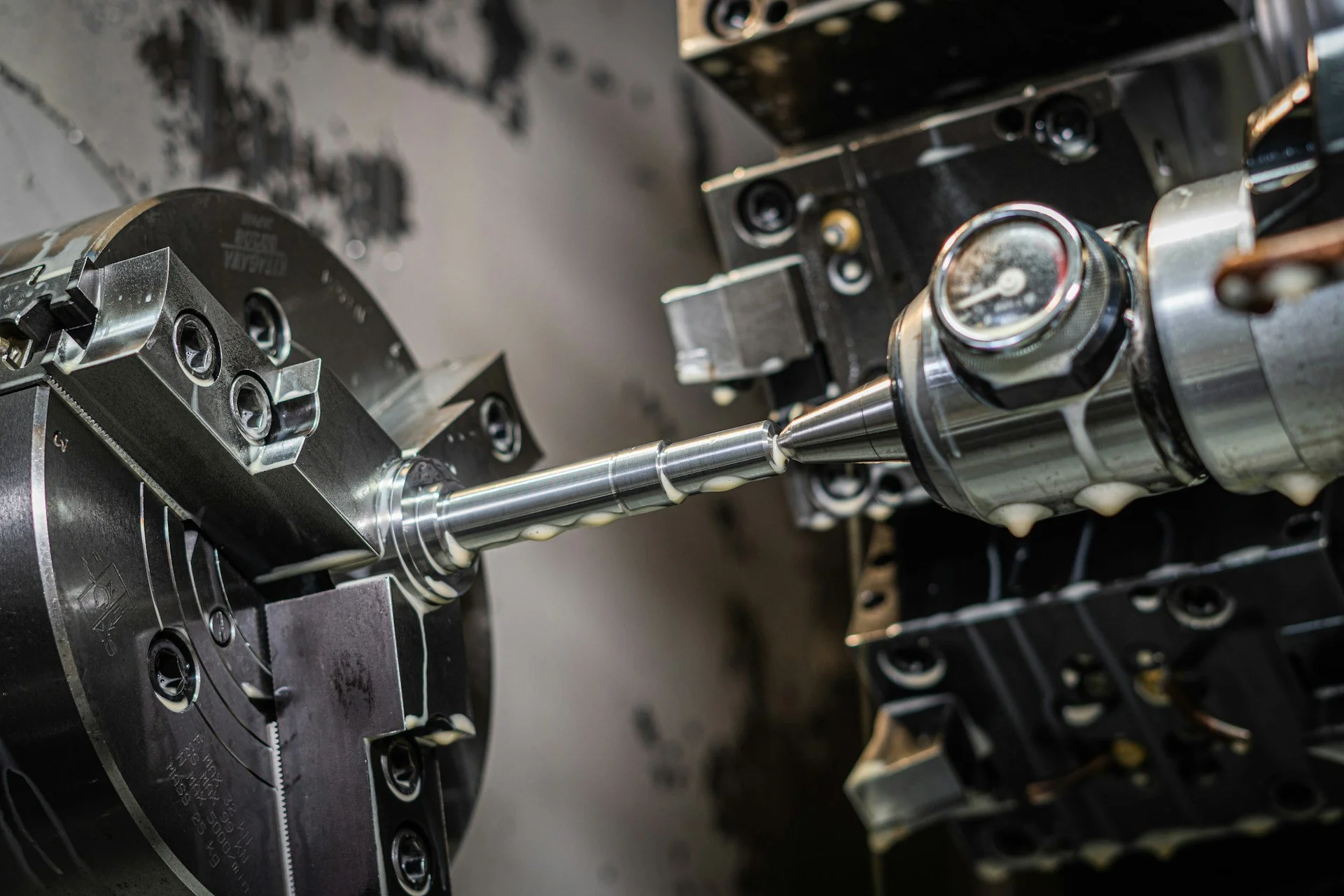

turning

Advanced Turning From Bar Stock to Finished Components

Our advanced CNC turning centers produce complex cylindrical parts with exceptional accuracy and surface finish. Live tooling and Y-axis capabilities allow for milling, drilling, and tapping operations in a single setup, reducing cycle times and improving part quality. With capacity to turn components up to 15 inches in diameter and 30 inches in length, we’re equipped to take on a wide range of manufacturing challenges with precision and reliability.

waterjet

Versatile Waterjet Cutting delivering clean, accurate results

Our OMAX 80X abrasive waterjet system cuts virtually any material, including metals, plastics, composites, and pre-hardened steels, without creating a heat-affected zone, mechanical stress, or warping. Ideal for thick plates and reflective materials, this process delivers precise results within ±0.005″ on parts up to 4″ thick, across a 13′ × 7′ working envelope.

welding & assembly

We provide certified welding services for the fabrication of complex assemblies and precision weldments. Our skilled technicians utilize both MIG (GMAW) and TIG (GTAW) processes to produce strong, reliable joints that meet the highest industry standards. Working with materials such as steel, stainless steel, and aluminum, we ensure every weld delivers exceptional strength, consistency, and durability.

What our customers say about us

"Cherry Creek Machine Shop has repeatedly exceeded our expectations with responsiveness and commitment to quality. Their team consistently delivers on time, communicates clearly, and produces quality work. We consider them a trusted partner and highly recommend their services."

——————————————

— Director of Quality, Sunvair Aerospace

“We are extremely pleased as to the conditions of the parts that we have been receiving. They are extremely clean and well made."

——————————————

— QA Team, Subsite Electronics

QUALITY

We are certified to the ISO 9001:2015 standard which drives continual improvement and customer satisfaction. Every process, from material receipt to final shipment, is planned, monitored, and verified to meet your requirements.

PRECISION ISN’T WHAT WE DO, IT’S WHO WE ARE

Founded in 2017, Cherry Creek Machine draws on more than three decades of precision machining experience and a legacy of craftsmanship that spans generations. What began as a small, dedicated job shop has grown into a modern CNC manufacturing partner trusted by leaders across aerospace, oil and gas, and other industries where precision is mission-critical.

Our leadership team brings multi-generational expertise in tight-tolerance manufacturing, having produced components for some of the most recognized names in the industry. That foundation of experience drives our commitment to quality, innovation, and integrity in every part we make.

Centrally located in Tulsa’s industrial hub

Cherry Creek Machine operates from 2045 E. 59th Place North, just minutes from downtown Tulsa and Tulsa International Airport. Our central location provides quick access to major highways, allowing us to deliver precision CNC machining, milling, and turning services efficiently to clients across Oklahoma and nationwide.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!